GL Industrial Solutions GmbH

At GL Industrial Solutions GmbH, we are your trusted partner in the engineering, production, and installation of complex industrial facilities.

We pride ourselves on our own engineering and project management office, own steel structure production facility and we execute on-site assembly projects on an industrial scale.

The Power of Acting as ONE.

Our strength lies in our dedicated team—engineers, workers, and both white- and blue-collar colleagues—working together as one. We oversee the entire process, from basic engineering to fabrication and final site assembly.

Our unique setup and competitiveness stem from our history. We started as a small engineering office, driven by a passion for integrating as much information as possible into the design phase. This pursuit of excellence, combined with our ambition, has shaped us into a company that not only provides a comprehensive overview of the entire process but also remains flexible in handling specific tasks.

Structural engineering

Basic and detail calculations acc. to national and international standards

Mechanical engineering

Plant layouts and detail calculations

Fabrication

Steel structures and industrial equipment up to EXC3

Complete plant installation

Steel and mechanical erection works

SERVICES

Your Partner in Industrial EPC Projects

A high level of customer satisfaction is the benchmark for the quality of our work. All our project implementation processes are planned and documented. If the circumstances change, they are adjusted if necessary. Comprehensively trained employees are deployed in all areas, so that everyone makes a significant contribution to the quality of the overall product through their work.

Engineering

Our in-house engineering office consists of more than 15 highly qualified structural and mechanical engineers with experience across various industrial sectors, including mining, cement, and energy.

We have developed efficient workflows to handle projects of all sizes, from small-scale tasks to large-scale developments involving hundreds of tons of steel and equipment. Our expertise covers everything from basic layouts to detailed execution.

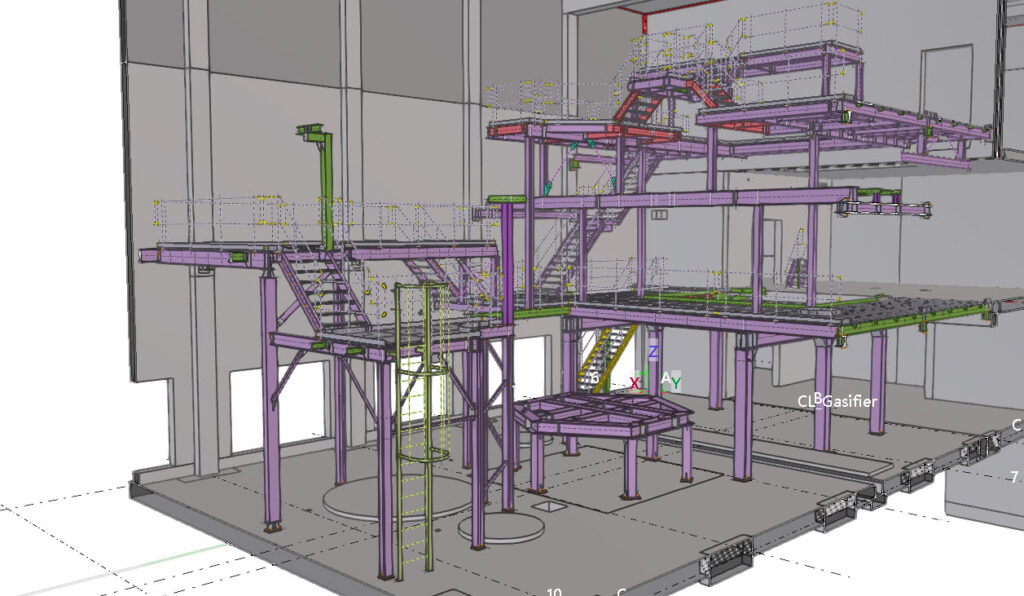

We utilize cutting-edge software for finite element (FE) calculations, modeling, and, when necessary, site 3D scanning. These advanced tools ensure precision and efficiency, particularly during installation.

Our engineering office leads ONE projects, where GL Industrial Solutions GmbH oversees the entire process, ensuring seamless execution from concept to completion.

Manufacturing

We strictly comply with internationally recognized certifications, ensuring quality, environmental responsibility, and industry best practices. Our welding plant certification is valid up to design class EXC-3 according to EN 1090-2:2008+A1:2011 standard, for procedure 135 (active shielded arc welding, solid wire, consumable electrode arc welding). Furthermore, our company has Welding Plant certification to the DIN EN ISO 3834-2 standard, which is intended to prove our ability to produce welding seams that meet the strictest quality requirements of our existing and future customers.

EN ISO 1090-2 EXC-3 – Compliance for load-bearing steel structures

EN ISO 3834-2 – Welding quality assurance for structural steel fabrication

ISO 9001 – Quality management system for consistent performance

ISO 14001 – Environmental management for sustainable operations

Our approach to projects centers on delivering comprehensive solutions tailored to our clients’ unique needs. With the capability to supply custom industrial equipment based on our own or client-provided documentation, we support a wide range of manufacturing requirements. We specialize in the production of unique components such as casings, flue gas ducts, silos, and cyclones, with or without internal refractory and external insulation as specified.

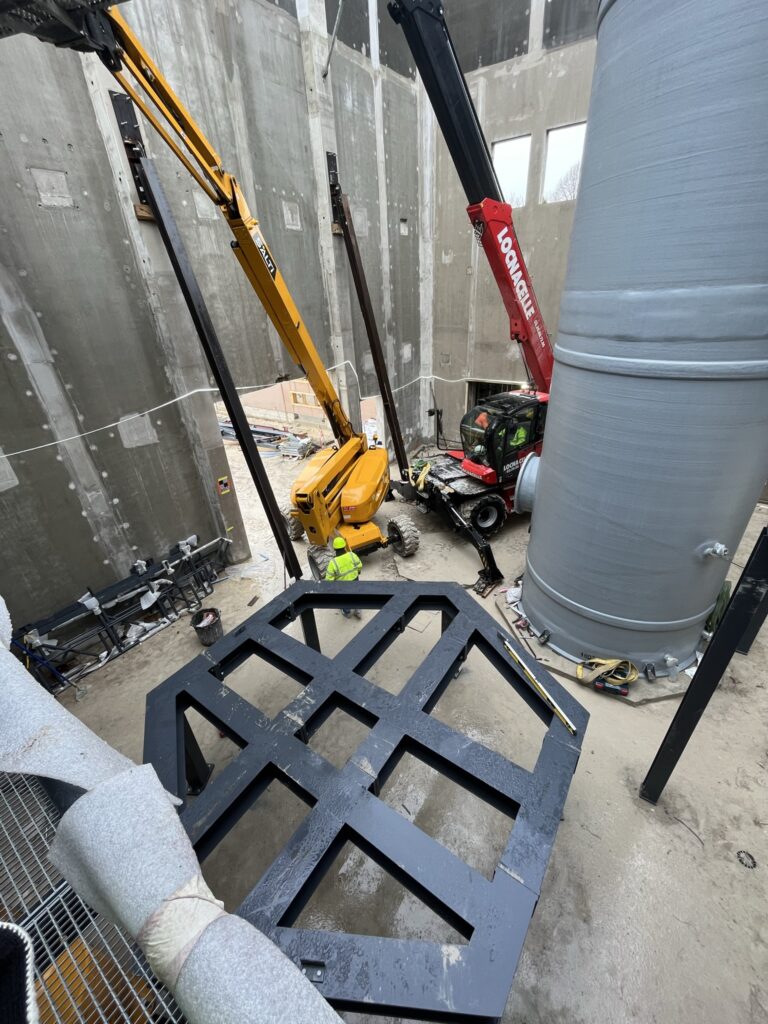

Installing

As your reliable partner from engineering through to manufacturing, we also offer full installation services as an EPC contractor. With extensive experience across Europe, and particularly within Germany, we ensure efficient and effective project execution. Our dedicated in-house crew allows us to optimize installation right from the engineering phase, providing a streamlined, smooth process tailored to your project’s needs.

Trust GL Industrial Solutions GmbH to bring strength, precision, and commitment to your most demanding projects.

ABOUT US

Your Partner in Industrial EPC Projects

At GL Industrial Solutions GmbH, we are your trusted partner in the engineering, production, and installation of complex industrial facilities. Headquartered in Nürnberg, Germany, our joint venture unites expertise from our engineering firm and a leading steel manufacturing company, enabling us to deliver seamless, integrated solutions for your projects.

We specialize in the engineering, fabrication, and installation of robust, high-quality steel structures for industrial applications. With decades of experience, advanced technology, and a dedication to excellence, we offer durable, cost-effective solutions tailored precisely to meet your needs.

Our Engineering Department provides comprehensive services, from static calculations of support structures to complex finite element analysis for industrial equipment. Whether you need support from project inception to completion or at specific stages, we are here to assist. We utilize industry-standard software for simulation, 3D modelling, and workshop drawing production, ensuring compatibility with a wide range of data formats for maximum flexibility and precision.

Why choose us

We are your trusted partner in the engineering, production, and installation of complex industrial facilities.

- Sustainablility

- Project On Time

- Modern Technology

- Complying with Latest Standards

PROJECTS

Georg Tveit

Ciments Vicat Xeuilley

CRH Medgidia

Biomass Plant

UK Bypass Project

Waste to Energy Germany

OI Glass

MOL Polyol

W-Scope

CATL

Mercedes Press Plant

Biomass Plant

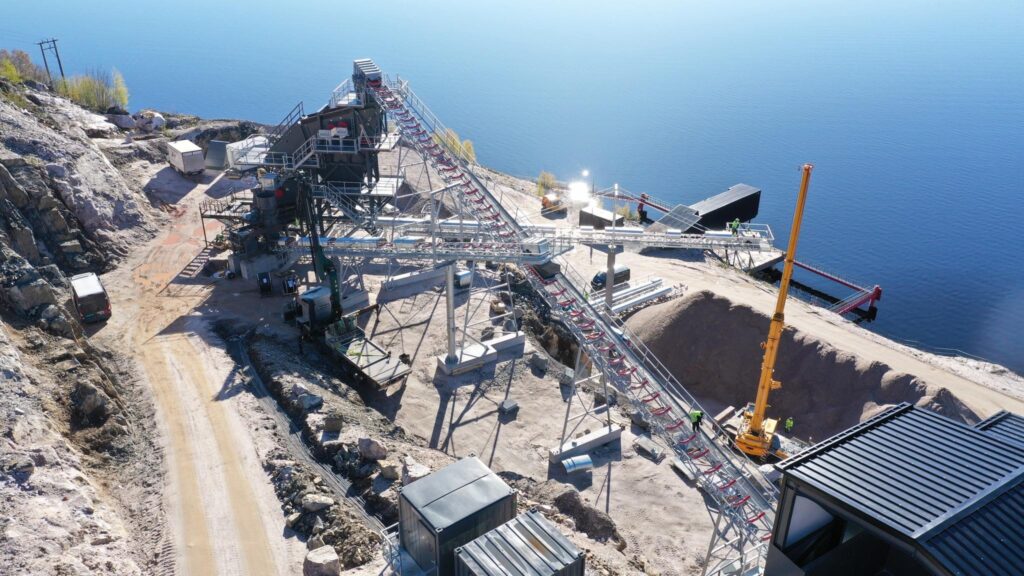

Sannidal, Norway

Task: prodution of the main steel structure, conveyor and crusher

The plant is designed to maximize the efficiency of the mass flow and make the best possible use of the location, including a short distance from quarry to crusher for dump trucks, and the plant is built so that the material-flow follows the gravity so that the energy requirement is reduced.

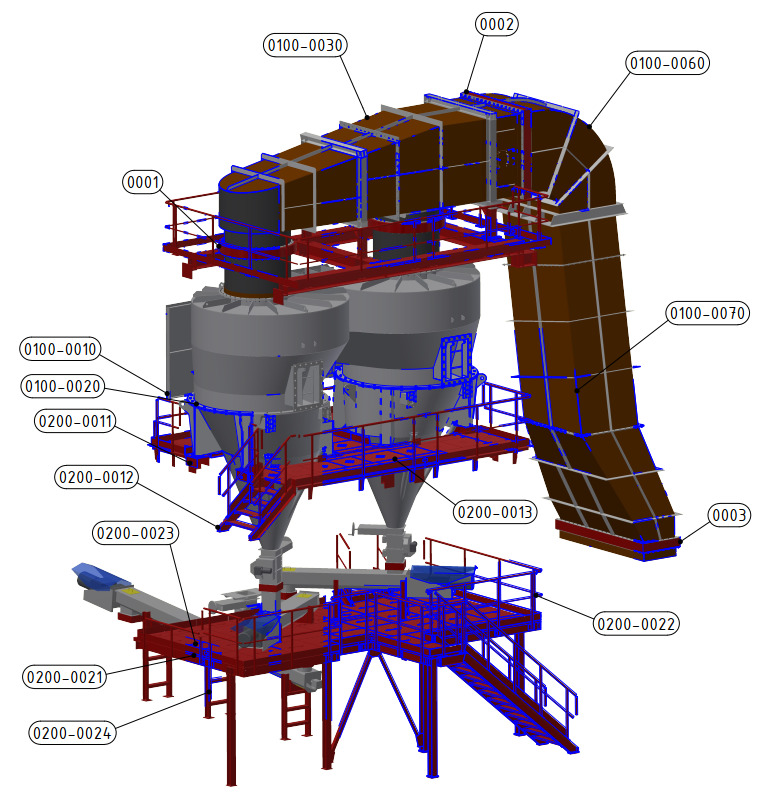

Xeuilley, France

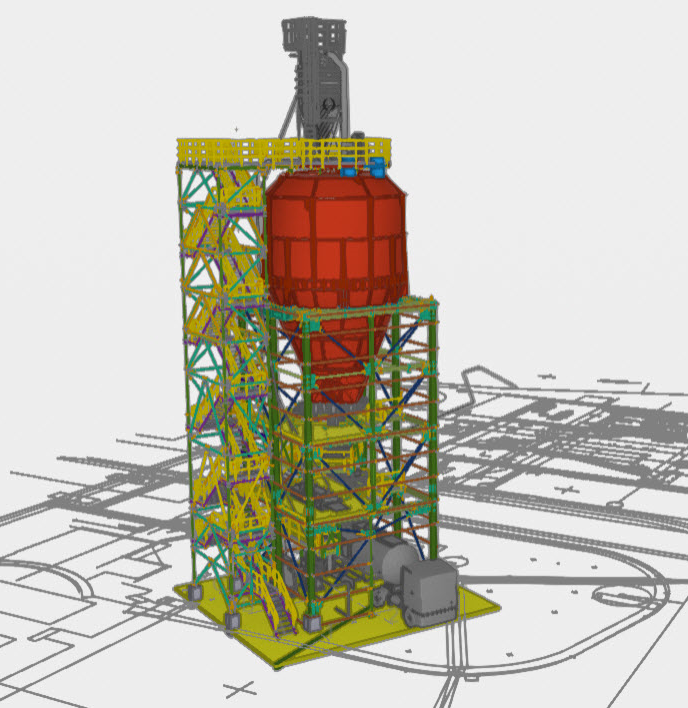

Task: Basic layout design, detail engineering and production of the steel structure, cyclones and gas ducts

This project came with several challenges, including confined spaces, limited information on the existing area, and—most critically—a very short delivery period. We had only 12 weeks to finalize the basic design, complete the detailed engineering, and finish production. Despite these constraints, our team successfully delivered, and the customer was highly satisfied with both our approach and our products.

Medgidia, Romania

Task: Basic layout design, detail engineering and production of the steel structure

We successfully met all regulatory requirements to deliver basic and detailed engineering to Romania, overcoming the challenge of strict earthquake standards. The fabrication process had to move quickly, as there was only a very short window for the plant to implement a temporary structure for its further operations.

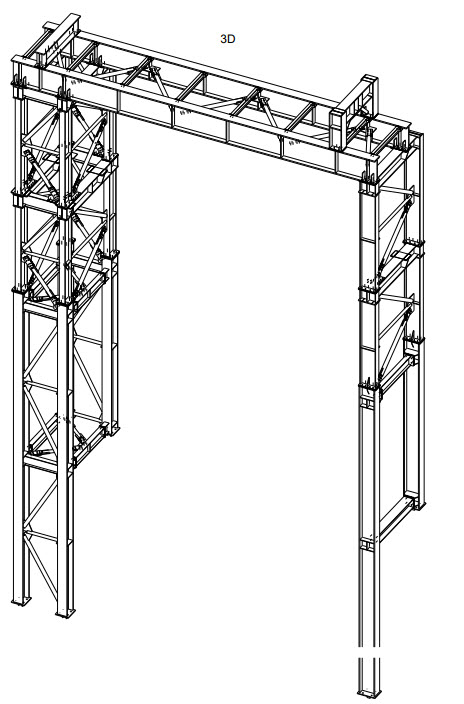

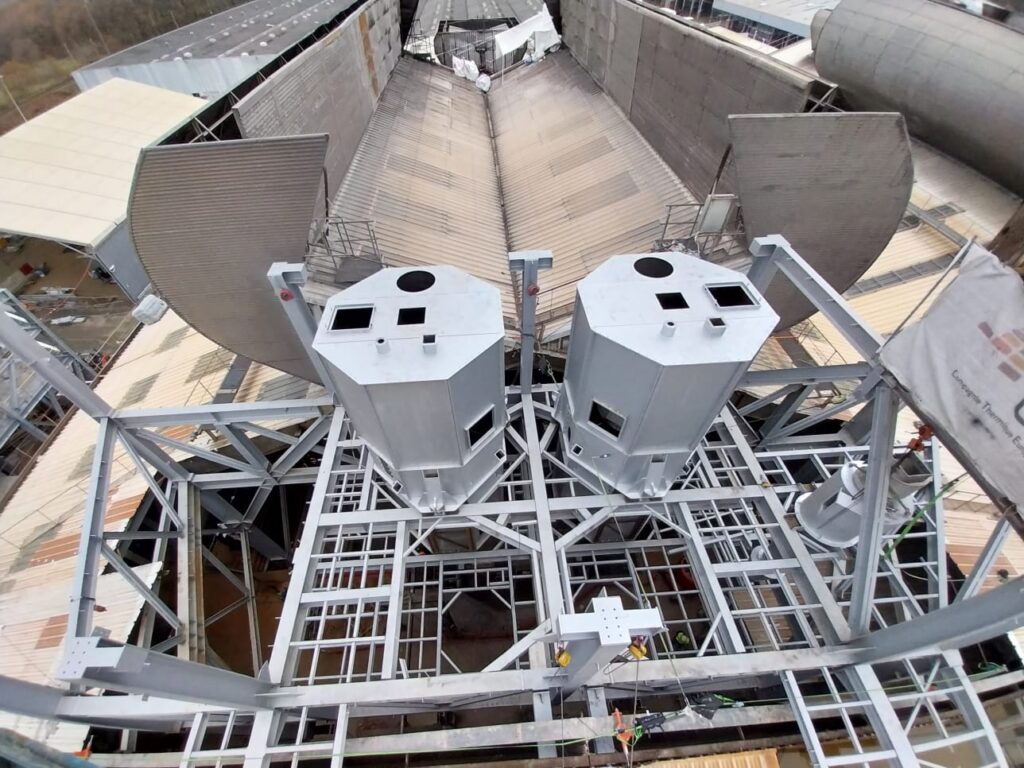

Amiens, France

Task: Basic and detail engineering, fabrication and installation of supporting steel structure

This was a typical “ONE” project, as we call it. It required our entire team and our unique approach, allowing us to influence and solve even the smallest details during the engineering phase—details that directly impact the efficiency of production and site erection. Despite local challenges, we were one of the few companies able to deliver on time without compromising quality.

Tunstead, United Kingdom

Task: Structural and detail engineering of the supporting structures, supply of lime hydrate silo and supporting steel

We were proud to contribute to this project with our expertise. Our scope included engineering and supplying the lime hydrate silo, ensuring seamless integration into the existing infrastructure. Through close collaboration and precise execution, we helped facilitate a more sustainable and efficient operation, reinforcing our commitment to innovative and forward-thinking industrial solutions.

Allmendingen, Germany

Task: Detail engineering of the steel structure, production and supply of all galvanized steel, and painted handrails

We successfully met all the necessary requirements to deliver approved engineering in full compliance with local regulations. Our ability to navigate complex standards and ensure high-quality design played a key role in the project’s success. As a result of our expertise and reliability, we were selected as the trusted supplier for the fabrication of all supporting steel structures.

Vayres, France

Task: design and production of the new interior structures which contained a 600 tons 54 m high tower and furnace structures.

Equally, in France, O-I Glass – one of the world’s leading container glass products, with operations in 10 European countries – invested 50 million euros in their plant in Vayres for a new Gas Oxy Advanced Technology furnace (GOAT). Their new GOAT furnace is equipped with an energy recovery system for heating raw materials, supplied by a new on-site oxygen production unit

Tiszaujvaros, Hungary

Task: production and installation of 1.000 tons of technology steel structure, piperacks and convayor

The project involved an international team of thousands of experts, with engineering design work carried out in Germany, Thailand, India and Hungary. The plant equipment came from 24 countries. The construction of the complex involved 75 000 cubic metres of concrete, 13 000 tonnes of steel, 2 500 kilometres of cable and 700 km of pipelines laid in more than 18 million working-hours.

Nyiregyhaza, Hungary

Task: design, production and installation of 820 tons of steel including piperacks, podiums, cable tracks and mechanical structres

This cutting-edge facility, dedicated to manufacturing essential components for electric vehicles, is not only one of the greatest investments in Hungary, but also holds promise for the local community. With plans to generate over 1,000 employment opportunities for the residents of Nyíregyháza and its vicinity, the factory is poised to significantly boost the city’s economic prosperity.

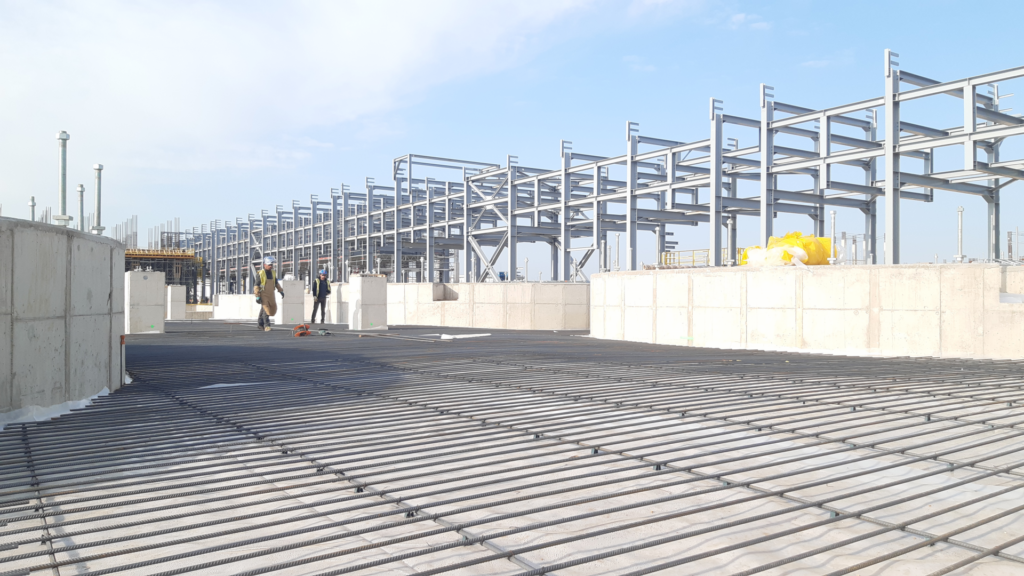

Debrecen, Hungary

Task: design, production and installation of 1.100 tons of steel including piperacks, interior and exterior stairs and podiums, frame structure

China-based CATL, a global leader in lithium-ion battery development and manufacturing picked Hungary as the location of its second European plant following the one in Germany. In addition, with its the proximity of plants of its customers such as Mercedes-Benz, BMW, Stellantis and Volkswagen, the Hungarian plant will enable CATL to better cope with the battery demands of the European market, improve its global production network development, and help accelerate e-mobility and energy transition in Europe.

Kecskemet, Hungary

Task: design and production of the interior steel structure

Production has started in the new 23.000 squere metre press plant of Mercedes-Benz factory in Kecskemét. The press plant will increase the the number of “Made in Kecskemét” parts worldwide, as it will also supply the Mercedes-Benz global production network with a wide variety of pressed steel and aluminium parts.

During operation – as it is already the case with the first press plant – the company attaches great importance to sustainability; almost 100% of waste materials generated in the future production processes will be recycled.

Kecskemet, Hungary

Task: design, production and installation of interior steel structure and cladding.

Veolia designed and built a 20+5 megawatt capacity renewable biomass power plant as part of a nearly 17 million Euro investment.

The fuel for the economical operation of the biomass heating plant can be sourced from the city’s selectively collected urban green biomass, including woody stems, sunflower hulls, and wood by-products from the timber industry that cannot be utilized for other purposes.

CONTACT US

Still have a question?

Contact us!

GL Industrial Solutions GmbH

Adlerstr. 34

90403 Nürnberg

Deutschland

Registration nr.: HRB 43776

Steuernummer: 241/127/50181

VIES nr.: DE450256545